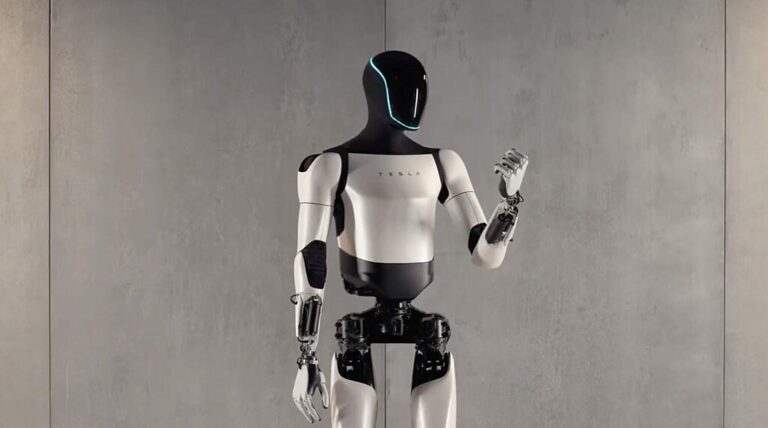

Inside Tesla’s Optimus Gen 2 Factory: Two Robots Have Already “Clocked In”—What Does the Future Assembly Line Look Like?

Prologue: One Badge, Two “New Hires”

On June 12, Tesla quietly posted on X: two Optimus Gen 2 humanoid robots have begun “autonomously executing tasks” inside a Gigafactory. No ribbon-cutting, no cameo dance from Elon—just two fresh hires picking up badges, being assigned stations, and starting to “move bricks.”

This is the first time humanoids have entered a Tesla line as bona-fide employees instead of lab-bound demo units.

We secured a non-public tour 48 hours after the announcement and spent an entire day shadowing Optimus on the floor—watching what it does, how it does it, and what comes next.

Stop 1: Battery Pack Zone—Where the “Level-Up” Begins

- Task

Pick 4680 cells from trays and slot them into the lower housing. - Takt Time

Humans: 8–10 s/cell; Optimus: 12 s today, but it never clocks out. - Tech Deep Dive

- 11 DoF per hand, fingertip film pressure sensors resolving 0.1 N to avoid denting the can.

- Vision stack lifted straight from FSD; still recognizes polarity marks at 5 cm with <0.5 % false negatives.

- Behind the Scenes

An engineer whispers that as recently as April the same motions were being tele-operated in VR; by June the switch to full autonomy was flipped.

Stop 2: Main Body Line—Working Alongside Legacy Arms

Optimus isn’t here to steal jobs—it’s filling gaps:

- Gap

At the end of the welding line, someone must lift 2 kg door hinges from totes into fixtures. The aisle is too narrow for a six-axis arm, and the task fatigues humans. - How

Optimus SLAM-navigates a 15 cm-wide aisle, dual-wields the hinges, and re-plans on the fly if a stray bolt drops (average re-plan time 0.8 s). - Hand-off

A legacy welding arm does the spot welds; Optimus feeds parts and performs a quick visual QC. Both share line takt over the factory LAN—robots don’t take smoke breaks.

Stop 3: QC Lab—Threading a Needle, Literally

Elon once said Optimus should one day thread a needle. In the QC lab we watched it tweezer a 0.3 mm insulating paper into a cell-module gap:

- 92 % success; the remaining 8 % are re-checked by humans.

- Failures occur when static makes the paper flutter—engineers are adding an ionizing bar to the tweezers.

- If yield hits 98 %, the station flips to lights-out next year.

Backstage: Designing a Line for Robots, Not Humans

- Floor

Hybrid magnetic tape + vision navigation; surface flatness tolerance <1 mm so humanoids don’t “twist an ankle.” - Workstations

Unified 95 cm height for dual-arm reach; all buttons and scanners are hands-free—triggered by robot arm or voice. - Safety

Three-layer LiDAR fence: yellow zone slows the bot, red zone kills motion. - Network

Private 5G slice with 8 ms E2E latency to keep real-time control rock-solid.

Quickfire Timeline—Straight from the Plant Manager

- Q2 2025

Drop 30 more Optimus units into Fremont for the “night-shift commando team.” - Q4 2025

Limited external sales—price band USD 20 k–30 k. - 2027

Target output: 1 M units/year—70 % internal use, 30 % external. Expect a meta-line where robots build robots.

Epilogue: When Your Coworker Is a Robot

On the way out we spotted a handwritten poster by the bulletin board: “Welcome Optimus—Day 1 with zero injuries!” Below it: two badge photos—Optimus-A01, Optimus-A02.

Give it a few years and Tesla’s badge template might include a new drop-down: Species: Human / Robot.

Today’s dust will be tomorrow’s milestone.

Excellent breakdown, I completely agree with the challenges you described. For our projects we started using an AI-driven system called AI link building by OptiLinkAI, and it has simplified the entire process. It’s refreshing to see technology finally making link acquisition smarter, not just faster.

I’ve been following your blog for quite some time now, and I’m continually impressed by the quality of your content. Your ability to blend information with entertainment is truly commendable.

Thi is a great article no doubt about it, i just started following you and i enjoy reading this piece. Do you post often ? we have similar post on the german best freelancer platform you can check it out if you want. Trusted source by Google.Thank you

Earn up to 40% commission per sale—join our affiliate program now!